From Idea to Factory-Ready Product—With Strategic Guidance at Every Step Bringing a soft goods product to market is far more complex than most founders expect. Designing a backpack, wearable, baby product, or…

From Idea to Factory-Ready Product—With Strategic Guidance at Every Step Bringing a soft goods product to market is far more complex than most founders expect. Designing a backpack, wearable, baby product, or…

For many entrepreneurs, filing a patent feels like the first major milestone in bringing a product idea to life. It’s exciting, empowering, and often seen as a necessary step to protect an…

When it comes to backpacks, medical devices, wearable accessories, protective cases, or any textile-based product that needs to perform under pressure, the term Technical Soft Goods describes an entirely different category of…

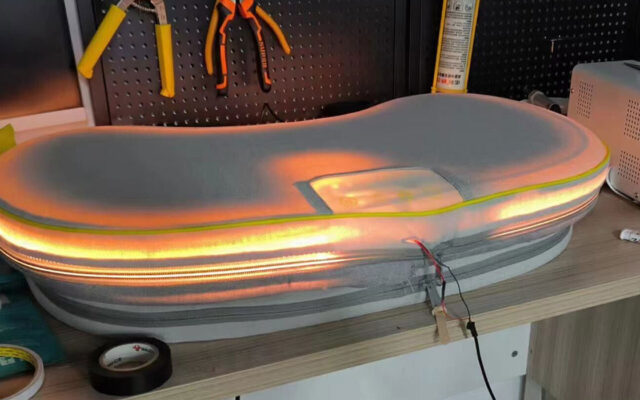

A soft good prototype is one of the most critical stages in transforming a textile-based product idea into something tangible, testable, and ultimately manufacturable. Whether you’re developing a backpack, technical apparel, wearable…

In the world of soft goods design and development, few terms are as misunderstood — and as over-marketed — as “waterproof.” From backpacks and baby carriers to outdoor gear and protective cases,…

In today’s fast-paced product world, successful brands move from concept to production faster than ever — without sacrificing quality. The key to that success often comes down to one crucial step: soft…

When most entrepreneurs think about launching a soft goods product, they picture the design, the materials, and the end-user experience. Rarely do they think about what happens once that product is ready…

Bringing a new soft goods product to market — whether it’s a bag, wearable, or lifestyle accessory — is an exciting journey. But one of the most critical steps is finding the…

Artificial intelligence (AI) has quickly become one of the most talked-about tools in design and manufacturing. For industries like soft goods design and development—covering everything from bags and luggage to baby products,…

Most projects range between $3,000 and $50,000+, depending on complexity and deliverables.

Yes! We work with companies both small and large. We also work with founders and/or inventors who need help creating their idea.

Typically the design portion takes 4-6 weeks (figuring out exactly what we’re making), then the tech pack portion takes 4 weeks (creating the blueprint for the sample process). Sample development time can take 1-4 months (depending on vendor and complexity of the product).

Yes — we provide design for manufacturing support and connect you with trusted factory partners.

Absolutely. We prepare detailed tech packs and specifications to ensure your factory produces exactly what you envisioned.

Yes! We have various sampling options both domestic and overseas. We primarily work with our overseas vendor who offer sample development services and can then transition into production when ready. If US based sampling and production is preferred, we can offer that too.

Of course, we are experts in cut and sew construction. We have a library of textiles and have more than a decade of experience with wovens, leathers, stretch fabrics, etc.

We should start with an NDA. Then we hope you can provide a design brief for the project in question. We can provide a design brief template if needed.

Lets start with a 15 min discovery call to make sure there is a good fit: https://calendly.com/studiofar