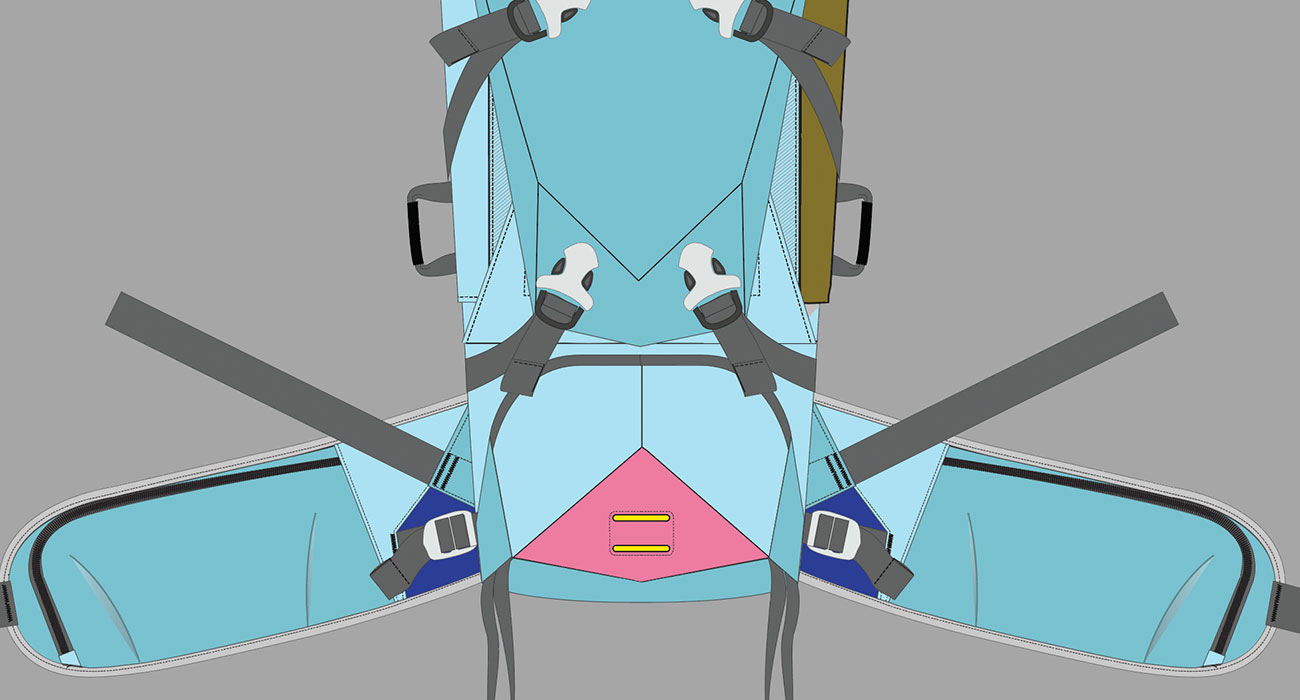

When it comes to backpacks, medical devices, wearable accessories, protective cases, or any textile-based product that needs to perform under pressure, the term Technical Soft Goods describes an entirely different category of design. These aren’t simple sewn items. They’re engineered products that blend industrial design, textile science, and manufacturing strategy.

At their core, technical soft goods require a thoughtful combination of high-performance materials, precise patterning, strategic layering, reinforcement techniques, ergonomic geometry, and manufacturable construction. Products in this category—like medical soft goods, technical packs, or wearable tech accessories—must be durable, repeatable in production, and comfortable to use. That level of performance doesn’t happen by accident; it happens through a structured design and development process.

Design: Function, Fit & Materials

The first stage of Technical Soft Goods Design focuses on how the product needs to work in the real world. That means selecting fabrics and foams that support durability, structure, and comfort—sometimes in multiple layers working together. It means defining load paths so seams and anchor points don’t fail under stress. And it means shaping the geometry so the product fits the body or the task correctly.

Good technical design considers usability, performance, and manufacturability from the start.

Development: Engineering a Repeatable Product

Technical soft goods go through a deeper level of development than typical sewn items. A full Bill of Materials, construction sequencing, and optimized patterning help ensure a factory can build the product consistently—whether in small batches or at scale. This phase is where we refine the product to meet quality targets, cost requirements, and performance needs.

Prototyping: Where Everything Gets Proven

Prototyping is where a product becomes tangible—and where any weaknesses are exposed. Iterations help evaluate structure, stress points, materials, and user experience. Most technical soft goods require several prototypes, with final validation samples once the factory takes over. This is the stage where performance gets confirmed or the design is optimized.

Understanding Technical Complexity

To help teams understand why technical soft goods require specialists, here’s a simple comparison chart showing typical complexity:

| Category | Material Complexity | Construction Complexity | Prototyping Difficulty |

|---|---|---|---|

| Everyday Bag | Low | Low | Low |

| Technical Backpack | Medium | Medium | Medium |

| Medical Soft Goods | High | High | High |

| Wearable Tech Goods | High | High | Very High |

| RF-Welded Waterproof Soft Goods | Very High | Very High | Very High |

Products higher on this chart require deeper experience, more iteration, and a tighter manufacturing setup.

Why It Matters

Great technical soft goods often look simple—but the engineering behind them is anything but. When designed well, they perform better, last longer, and are easier to manufacture. For brands and startups, partnering with a studio that understands the nuances of material science, pattern engineering, technical construction, and global manufacturing can dramatically reduce risk and increase product success.

If you’re developing a technical soft goods product or improving an existing design, Studio FAR can help guide you through the process with clarity, precision, and real-world manufacturing expertise.

Ready to Build Your Prototype?

If you’re serious about bringing your soft goods product to market, don’t skip the prototype — and don’t settle for a quick-and-dirty sample. Work with a partner who understands every stitch, panel, and production step ahead.

Let’s talk. Book a consultation to start your soft goods prototype today.

We’ll help you go from napkin sketch to sample to scalable, manufacturable product — without wasted time, blown budgets, or preventable setbacks.

https://calendly.com/studiofar/15min