So you’ve got a great product idea — maybe it’s a smart backpack, a modular baby carrier, or a sleek wearable accessory. You’ve even created some detailed sketches or a CAD drawing. But when you reach out to a manufacturer, the conversation stalls. They ask for something you didn’t realize you’d need: a tech pack.

If you’re wondering what a tech pack is (and why your sketch isn’t enough), you’re in the right place.

In this post, we’ll break down:

-

What a tech pack actually is

-

Why it’s essential for soft goods manufacturing

-

What goes into a great tech pack

-

How it saves you time, money, and production headaches

What Is a Tech Pack?

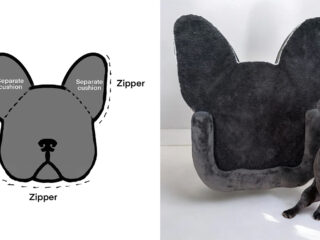

A tech pack (short for “technical package”) is a detailed blueprint that tells a manufacturer exactly how to build your product — every stitch, panel, zipper, and seam.

Think of it like architectural plans for a building. You wouldn’t build a house with just a floor sketch — you’d need measurements, material specs, structural notes, and more. The same goes for your soft goods product.

Why a Sketch Alone Doesn’t Cut It

A sketch might show what the product should look like, but it doesn’t tell the factory how to make it.

Without a tech pack, manufacturers have to guess:

-

What materials should they use?

-

What size should the components be?

-

How should the parts be constructed?

-

What tolerances are acceptable?

-

How should packaging be handled?

These unknowns lead to:

-

Miscommunication

-

Repeated sampling rounds

-

Delays and increased costs

-

A final product that doesn’t match your vision

What’s Included in a Good Tech Pack?

A proper soft goods tech pack includes all the details your manufacturer needs to bring your product to life accurately and efficiently. Here are the essential components:

Cover Page / Product Overview

-

Product name

-

Style number

-

Category

-

Season (if applicable)

-

Visual render or flat sketch

Technical Drawings

-

Front, back, and side views

-

Construction callouts (stitch types, paneling, pockets, closures)

Materials List (BOM – Bill of Materials)

-

Fabric types

-

Trims (zippers, buckles, straps, etc.)

-

Lining and padding

-

Hardware specs

Measurements & Sizing

-

Dimensions for every panel and component

-

Tolerances allowed for variation

Construction Details

-

Stitch types

-

Seam allowances

-

Finishings (binding, edge taping, topstitching)

Labeling & Packaging

-

Hangtags

-

Woven labels

-

Packaging requirements

-

Folding/boxing instructions

Colorways & Variants

-

Swatches or Pantone codes

-

Alternative versions (if applicable)

How a Tech Pack Saves Time and Money

A tech pack isn’t just a design tool — it’s a business asset. Here’s how it protects your investment:

1. Fewer Revisions

Clear, complete instructions reduce the back-and-forth between you and the factory. That means faster prototyping and fewer expensive mistakes.

2. Accurate Costing

Factories use the tech pack to calculate labor time, material usage, and manufacturing costs with precision. That gives you clearer pricing from the start.

3. Manufacturer Accountability

With all expectations documented, you have a reference point to ensure your product is built to spec.

4. Easier Factory Handoff

If you switch manufacturers or scale up production, your tech pack ensures consistent quality across suppliers.

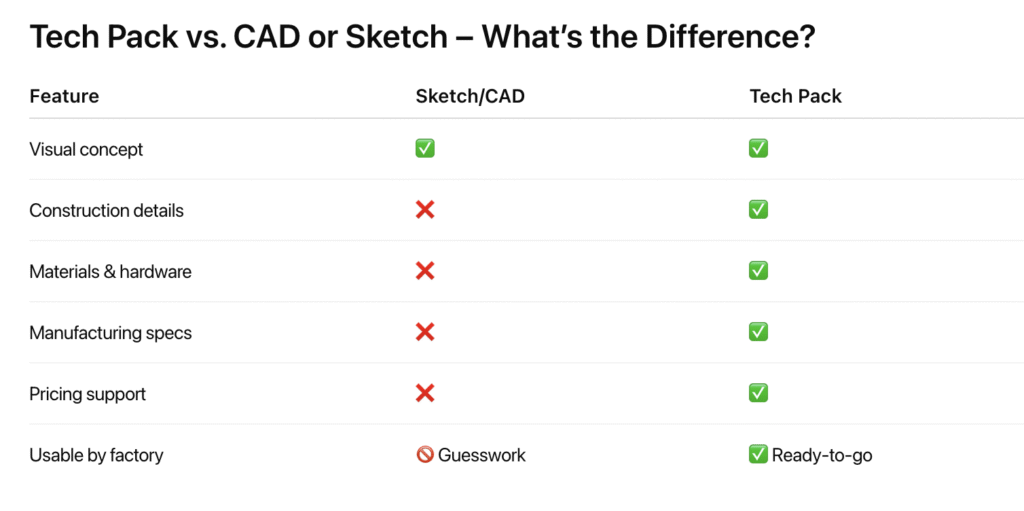

Tech Pack vs. CAD or Sketch – What’s the Difference?

Do You Need a Tech Pack?

If you’re developing any product that will be mass-produced, the answer is yes. A tech pack is essential to:

-

Translate your idea into production-ready specs

-

Avoid miscommunication with manufacturers

-

Get accurate pricing and lead times

-

Ensure consistent quality

Even if you’re early in your product development journey, investing in a tech pack can save thousands of dollars in production fixes and delays.

Need Help Creating a Professional Tech Pack?

That’s what I do.

I’ve worked with founders and startups across industries — from bags and baby products to medical wearables — helping them design, prototype, and launch successful soft goods products.

Whether you’re starting from a sketch or refining a prototype, I can build a custom tech pack that bridges the gap between your idea and real-world manufacturing.

Feel free to schedule a call here: