From Idea to Factory-Ready Product—With Strategic Guidance at Every Step

Bringing a soft goods product to market is far more complex than most founders expect. Designing a backpack, wearable, baby product, or technical soft good isn’t just about aesthetics—it’s about manufacturability, materials, construction, cost targets, overseas production realities, and risk management.

At studioFAR, I work as a turnkey soft goods product development partner, helping founders and early-stage brands turn ideas into production-ready soft goods products—without guessing their way through design, prototyping, and manufacturing.

This article explains what a turnkey approach to soft goods development really means, why it matters for startups, and how studioFAR supports founders as a strategic consultant, not just a hired designer.

Why “Turnkey” Matters in Soft Goods Development

Many founders approach product development thinking they need:

- A designer for sketches

- A factory for samples

- A tech pack at the end

In reality, these steps are deeply interconnected—and skipping strategic decision-making early often leads to expensive mistakes later.

A turnkey soft goods development approach means:

- One experienced partner guiding the entire process

- Decisions made with manufacturing, cost, and scalability in mind

- Fewer surprises during sampling and production

Rather than handing off fragmented work to multiple vendors, studioFAR provides end-to-end guidance—from concept through factory-ready documentation.

More Than Design: A Consulting-Led Approach

While industrial design and soft goods design are core capabilities, my role goes far beyond creating concepts or CAD files.

I help founders answer critical questions like:

- Is this product actually manufacturable at scale?

- What materials and construction methods make sense for cost and durability?

- What needs to be proven through soft goods prototyping before filing patents or placing large orders?

- Which overseas factories can realistically execute this product?

With nearly 15 years of experience in soft goods design and development, I’ve seen where products fail—not because of bad ideas, but because of poor early decisions.

That’s why studioFAR operates as a consultant and strategic partner, not just a design vendor.

The Turnkey Soft Goods Development Process at studioFAR

1. Concept Evaluation & Strategy

Every project starts with understanding:

- The product vision

- Target customer and use cases

- Performance requirements

- Budget and production goals

This phase reduces risk by identifying constraints early—before time and money are spent on the wrong solutions.

2. Technical Soft Goods Design

Design decisions are made with manufacturing in mind:

- Pattern architecture

- Stitching and seam construction

- Reinforcement strategies

- Hardware and trim selection

This ensures the product isn’t just visually compelling—but buildable, durable, and scalable.

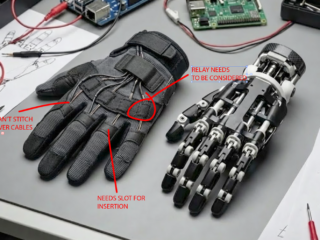

3. Soft Goods Prototyping & Iteration

Prototyping is where ideas meet reality.

Through hands-on cut-and-sew soft goods prototyping, we:

- Validate construction methods

- Test ergonomics and functionality

- Refine materials and components

- Identify cost drivers early

This step is essential for startups and early-stage brands. Skipping or rushing prototyping often leads to failed samples, blown budgets, or compromised quality.

4. Materials, Fabrics & CMF Strategy

Selecting the right materials is one of the most critical decisions in soft goods development.

studioFAR supports:

- Fabric and textile selection

- Performance requirements (abrasion, waterproofing, durability)

- Color, material, and finish (CMF) strategy

- Supplier compatibility with overseas factories

Every material choice impacts cost, lead time, and manufacturability.

5. Factory Coordination & Overseas Manufacturing Support

Many founders underestimate how challenging overseas manufacturing can be.

I act as the bridge between:

- Your product vision

- Factory capabilities

- Real-world production constraints

This includes:

- Factory vetting and alignment

- Tech pack preparation

- Sampling coordination

- Feedback and iteration with manufacturers

The goal isn’t just to “get a sample”—it’s to arrive at production-ready soft goods documentation.

Who This Turnkey Approach Is For

studioFAR works best with:

- Founders and startups developing soft goods for the first time

- Early-stage brands preparing for production or fundraising

- Teams that need guidance—not just deliverables

Common product categories include:

- Backpacks and travel goods

- Wearables and technical accessories

- Baby and juvenile products

- Medical and healthcare soft goods

- Automotive and industrial accessories

If you’re building a physical product that must survive real-world use and manufacturing constraints, a turnkey approach dramatically improves your odds of success.

Why Founders Choose studioFAR

My role isn’t just to design products.

It’s to help you:

- Avoid costly manufacturing mistakes

- Make informed decisions before spending serious capital

- Build products that are manufacturable, durable, and commercially viable

- Work with overseas factories that can actually execute

By combining design expertise, hands-on prototyping, and manufacturing insight, studioFAR helps founders move forward with clarity and confidence.

Final Thoughts: From Idea to Production, With Fewer Surprises

Soft goods product development is still a craft—one that requires experience, judgment, and practical knowledge.

By working with studioFAR as a turnkey soft goods consultant, founders gain more than design files. They gain a partner who understands how products behave in the real world—and how to guide them from concept to factory-ready production.

If you’re developing a soft goods product and want a clear, strategic path forward, studioFAR is built to support you every step of the way.

Ready to Build Your Prototype?

If you’re serious about bringing your soft goods product to market, don’t skip the prototype — and don’t settle for a quick-and-dirty sample. Work with a partner who understands every stitch, panel, and production step ahead.

Let’s talk. Book a consultation to start your soft goods prototype today.

We’ll help you go from napkin sketch to sample to scalable, manufacturable product — without wasted time, blown budgets, or preventable setbacks.

https://calendly.com/studiofar/15min