A soft good prototype is one of the most critical stages in transforming a textile-based product idea into something tangible, testable, and ultimately manufacturable. Whether you’re developing a backpack, technical apparel, wearable gear, medical soft goods, or accessories, your prototype sets the foundation for everything that follows. It’s where concepts evolve into real, physical objects — and where design assumptions meet the reality of material behavior, durability, and user experience.

In the world of product development, a soft good prototype is far more than a sample. It’s a tool for validation, iteration, storytelling, and alignment across design, engineering, marketing, and manufacturing teams. In many ways, it is the moment your idea becomes real.

What Is a Soft Good Prototype?

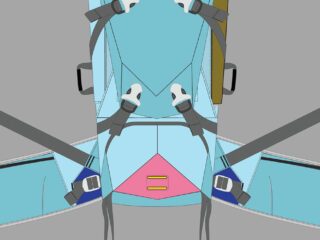

A soft good prototype is a preliminary, physical version of a textile-based product created to test design intent, dimensions, construction techniques, material selection, and usability. Unlike digital renderings or flat sketches, a prototype lets you evaluate how materials drape, stretch, insulate, resist abrasion, or respond to stress — all of which influence the final product’s performance.

Soft goods often include:

- Bags, backpacks, and luggage

- Outdoor gear (tents, sleeping bags, hydration packs)

- Wearable tech and sensor-integrated garments

- Protective equipment

- Medical braces, supports, and therapeutic wearables

- Fashion and lifestyle accessories

Because these items rely on fabric, foam, film, hardware, and stitching methods, prototyping requires specialized knowledge that blends industrial design, patternmaking, and hands-on fabrication.

Why a Soft Good Prototype Matters More Than Ever

Today’s consumers demand products that combine performance, durability, and sustainability. As expectations rise, a soft good prototype becomes the single most effective way to refine the user experience before investing in tooling, materials, or mass production.

Some of the biggest advantages include:

1. Testing Fit and Functionality

Physical prototypes allow you to evaluate real-world use cases:

- Does the pocket placement feel intuitive?

- Does the strap length support multiple body types?

- Does the zipper glide smoothly under tension?

- Does the material behave correctly when packed, stretched, or folded?

These insights are impossible to fully capture in digital files alone.

2. Material Validation

Textile-based products depend on how materials actually behave. You can assess:

- Stretch, rigidity, and drape

- Moisture resistance and breathability

- Abrasion and tear strength

- Weight and packability

Choosing the wrong material can derail an entire product, so early validation is essential.

3. Cost and Manufacturing Feasibility

A soft good prototype also reveals how complex a design really is. Patternmakers and sewing technicians can flag:

- Difficult seam lines

- High-labor construction methods

- Hardware placement challenges

- Opportunities for cost-saving simplification

This prevents surprises when the product reaches a factory.

4. User Feedback You Can Actually Use

A prototype turns vague opinions into actionable direction. Test users can interact with the product, provide emotional responses, and surface real-world challenges you may have missed during design.

The Stages of Creating a Soft Good Prototype

Every team has its own workflow, but most soft good prototyping processes follow these core phases:

Concept Development

This stage involves sketches, inspiration, user insights, and initial requirements. The goal is to define what the product should achieve and how it should look.

Patternmaking

Patternmaking translates ideas into 2D templates that shape your final product. Expert patternmakers play a crucial role in ensuring proper fit, symmetry, and structural integrity.

Material Selection

You refine fabric choices, foam densities, hardware styles, and trims. Material choice impacts cost, performance, and durability.

Sample Sewing

The prototype is constructed by hand or with specialized industrial machines. Skilled sample makers use techniques such as:

- Edge binding

- Bartack reinforcement

- Seam taping

- Foam lamination

- Precision topstitching

This stage provides your first real sense of the product’s identity.

Review and Iteration

After you examine the prototype, you adjust the pattern, revise construction, and make improvements. Most soft good products go through multiple iterations before approval.

How to Choose the Right Soft Good Prototyping Partner

Your prototyping partner directly affects quality, speed, and manufacturability. Look for a team with experience across design, engineering, and sewn-goods fabrication. Specifically, you want partners who understand patternmaking, CAD drafting, materials science, and small-batch construction.

A strong collaborator will guide you through questions such as:

- How should the product be reinforced?

- Which materials perform best for your intended use case?

- Will your design face production challenges overseas?

- Are there simpler, more durable ways to construct key features?

The right partner doesn’t just build prototypes — they help you build a better product.

From Prototype to Production

Once your soft good prototype is finalized, you’re ready for:

- Technical packs

- Factory-ready CAD files

- Material sourcing

- Costing estimates

- Manufacturing samples

Your prototype becomes your roadmap, your benchmark, and your storytelling tool for investors, retailers, and marketing teams.

Final Thoughts

A soft good prototype isn’t just a milestone — it’s the heart of the product development journey. It’s where ideas take shape, where problems reveal themselves, and where innovative solutions emerge. Whether you’re a startup founder, a designer, or a product manager, investing in high-quality prototyping is the clearest path toward creating soft goods that people love, trust, and rely on.

Ready to Build Your Prototype?

If you’re serious about bringing your soft goods product to market, don’t skip the prototype — and don’t settle for a quick-and-dirty sample. Work with a partner who understands every stitch, panel, and production step ahead.

Let’s talk. Book a consultation to start your soft goods prototype today.

We’ll help you go from napkin sketch to sample to scalable, manufacturable product — without wasted time, blown budgets, or preventable setbacks.

https://calendly.com/studiofar/15min