For many entrepreneurs, filing a patent feels like the first major milestone in bringing a product idea to life. It’s exciting, empowering, and often seen as a necessary step to protect an idea before sharing it with the world.

However, when it comes to soft goods products—such as bags, backpacks, wearables, baby products, or technical sewn goods—filing a patent too early can actually create unexpected challenges later in the development process.

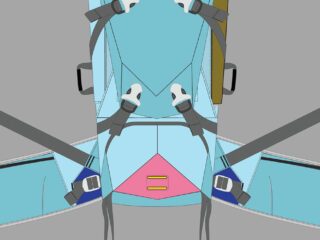

Before filing a design patent or utility patent, it’s critical to understand how soft goods are actually designed, constructed, and manufactured. Unlike rigid products, soft goods rely on cut-and-sew construction, flexible materials, and layered assemblies that often evolve significantly once a concept is tested in the real world.

The Common Mistake: Patenting an Unrealized Soft Goods Concept

One of the most common scenarios I see is a founder approaching studioFAR with a patent already filed—based on a sketch, rendering, or theoretical concept. On paper, the idea looks sound. But once we begin the soft goods design and development process, it becomes clear that the product needs to change.

This is not because the idea was bad—but because soft goods behave differently in reality. Fabric drapes. Seams introduce bulk. Zippers, foams, reinforcements, and stitch lines all affect function, comfort, and manufacturability.

When those changes happen after a patent is filed, founders can find themselves locked into protecting a version of the product that no longer reflects what’s actually possible—or desirable—to manufacture.

Why Soft Goods Require Prototyping Before Patents

Soft goods are inherently iterative. A product might look one way in a sketch but behave entirely differently once sewn and assembled. This is why soft goods prototyping is such a critical step before filing any intellectual property.

Prototyping allows designers and founders to:

- Validate cut-and-sew construction methods

- Test materials and layered assemblies

- Understand structural requirements

- Identify stress points and failure areas

- Refine proportions, fit, and usability

These insights directly influence the final form and function of the product—information that is invaluable when determining what should actually be patented.

Design Patent vs. Utility Patent in Soft Goods

Understanding the difference between patent types is especially important in soft goods development.

A design patent protects the ornamental appearance of a product. For soft goods, this might include the overall silhouette, seam layout, or unique visual elements. However, if the design changes during development—as it often does—the protection may no longer fully apply.

A utility patent protects how something works. In soft goods, this could relate to a unique closure system, carry method, internal structure, or functional feature. These inventions are often discovered during prototyping, not before it.

In both cases, filing too early—before design, development, and prototyping—can limit flexibility and reduce the value of the patent itself.

The Role of a Soft Goods Designer Before Filing

Working with an experienced soft goods designer before filing a patent helps ensure that what you’re protecting is grounded in reality. At studioFAR, the focus is on taking an idea and transforming it into a proven concept—one that has been thoughtfully designed, prototyped, and evaluated for manufacturing.

This process helps founders:

- Avoid patenting features that won’t survive development

- Identify the true innovations worth protecting

- Align design intent with manufacturing realities

- Reduce costly redesigns later

Instead of filing a patent based on assumptions, founders are able to file with confidence—knowing the product has been physically explored and refined.

Cut-and-Sew Construction Changes Everything

Unlike injection-molded or machined products, soft goods are built from patterns, panels, and seams. Every stitch line matters. Construction choices affect durability, cost, and performance.

Through cut-and-sew prototyping, designers uncover opportunities for improvement that rarely appear in early sketches. A seam might move for strength. A panel might split for better assembly. A closure system might simplify.

These decisions directly influence what should—or shouldn’t—be protected by a patent.

A Smarter Path Forward

The most successful founders don’t rush to file. Instead, they:

- Develop the concept with a professional soft goods designer

- Build and test functional prototypes

- Refine the design for real-world use and manufacturing

- Then work with a patent attorney to protect the right aspects

This approach saves time, money, and frustration—and results in stronger intellectual property.

Final Thoughts

Patents are powerful tools, but only when they protect something real. In soft goods design and development, reality emerges through prototyping, iteration, and hands-on exploration.

Before filing a design or utility patent, invest in the process of making your idea tangible. Working with a studio like studioFAR ensures that what you protect is not just an idea—but a thoughtfully designed, manufacturable product.

Ready to Build Your Prototype?

If you’re serious about bringing your soft goods product to market, don’t skip the prototype — and don’t settle for a quick-and-dirty sample. Work with a partner who understands every stitch, panel, and production step ahead.

Let’s talk. Book a consultation to start your soft goods prototype today.

We’ll help you go from napkin sketch to sample to scalable, manufacturable product — without wasted time, blown budgets, or preventable setbacks.

https://calendly.com/studiofar/15min