Bringing a new soft goods product to life — whether it’s a travel bag, wearable tech accessory, baby product, or automotive add-on — is an exciting journey. But for many entrepreneurs and startups, the excitement quickly gives way to frustration. From prototyping problems to production delays, there are countless ways a great idea can go wrong.

The good news? With the right process, expert support, and smart decision-making, you can avoid the most common (and expensive) mistakes — and launch your product into the market with confidence.

In this article, we’ll walk through:

- The most common pitfalls product entrepreneurs face

- A step-by-step roadmap from concept to scalable manufacturing

- How to choose reliable manufacturers

- Why design-for-manufacturing and project management are make-or-break

The Most Common Pitfalls When Launching a Soft Goods Product

Even well-funded, experienced entrepreneurs can hit roadblocks when developing a physical product — especially in the soft goods category. Here are a few of the biggest challenges I see clients face before working with me:

1. Prototypes That Can’t Be Manufactured

A prototype may look great, but if it isn’t designed with real production methods in mind, it can’t scale. This is one of the most common causes of delays and blown budgets.

2. Sourcing the Wrong Manufacturer

Not every factory is created equal. Some don’t specialize in soft goods. Others may struggle with quality control, communication, or low minimums — all of which can compromise your launch.

3. Skipping the Design for Manufacturing (DFM) Phase

You can’t just “hand off” a sketch to a factory. Your product needs to be engineered for efficiency, cost, material sourcing, and repeatability. Missing this phase often leads to redesigns and extra rounds of sampling.

4. Underestimating Timelines and Costs

Launching a product isn’t a straight line. Without clear project management, even small delays can snowball into missed seasonal launches or lost funding.

The Step-by-Step Process for Developing Your Product

Here’s a simplified breakdown of the product development journey — built specifically for soft goods:

1. Concept & Research

Whether you’re solving a personal problem or innovating in a market category, everything starts with validating the need. Define the core function, target user, and competitive landscape.

2. Industrial Design & Sketches

This is where your vision takes form. Through hand sketches, digital renderings, and material exploration, your idea starts becoming a tangible product.

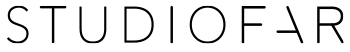

3. Prototyping

Prototypes help you test form, fit, function, and construction. You may go through multiple versions to refine features, materials, and user experience.

4. Design for Manufacturing (DFM)

This is where we translate the design into a format factories can work with — tech packs, BOMs, specs, construction methods, stitch types, trims, packaging, and more.

5. Manufacturer Sourcing

We identify and vet manufacturing partners based on your product’s needs — materials, production scale, MOQ, pricing, and ethical standards.

6. Production Management

Once sampling is complete, the real production process begins. With proper oversight, you can prevent quality issues, missed deadlines, and costly surprises.

How to Choose the Right Manufacturer

The factory you choose can make or break your product. Here’s what to look for:

- Soft Goods Experience – Do they specialize in your product category (bags, baby, footwear, etc.)?

- Communication Clarity – Do they understand your goals and ask the right questions?

- Quality Control Systems – Can they show proof of consistency and standards?

- Scalability – Can they grow with your brand as your order volumes increase?

Don’t go it alone. If you’re not familiar with vetting factories, introductions through an experienced designer or consultant can save you months of trial and error.

Why Design-for-Manufacturing & Project Management Matter

These two areas are where most early-stage brands lose time and money:

Design-for-Manufacturing (DFM):

You can’t assume a beautiful design will translate into an efficient product. DFM ensures your product is:

- Cost-efficient to produce

- Easy to assemble at scale

- Repeatable in quality

- Aligned with available materials

Project Management:

From sample rounds to factory coordination, you need someone keeping timelines, deliverables, and communication in sync. A missed follow-up can cost you a full production cycle.

When you work with someone who deeply understands both design and production, you avoid costly delays, endless revisions, and lost momentum.

Ready to Launch Your Product the Right Way?

You don’t need to figure it all out yourself. I’ve helped dozens of founders and product teams take their soft goods ideas from napkin sketch to finished product — ready for e-commerce, retail, or investor showcases.

If you’re ready to turn your idea into a market-ready, scalable product — without wasting time or budget — let’s talk.

Feel free to schedule a call here: