In the world of soft goods design and development, few terms are as misunderstood — and as over-marketed — as “waterproof.” From backpacks and baby carriers to outdoor gear and protective cases, understanding how water resistance actually works can make or break your product’s performance and reputation.

At studioFAR, we help clients design and prototype soft goods with the right level of water protection — not overbuilt, not underperforming, but precisely engineered for the intended environment and user needs.

1. The Three Levels of Water Protection in Soft Goods

When developing a soft goods prototype, it’s essential to define whether your product needs to be water-resistant, waterproof, or submersible. These terms aren’t interchangeable — they describe different construction techniques, materials, and performance levels.

| Level | Typical Use Case | Fabric & Coating Type | Construction Method | Water Ingress Rating |

|---|---|---|---|---|

| Water-Resistant | Light rain, splashes | DWR (Durable Water Repellent) coatings | Standard stitched seams | Minimal resistance — short exposure |

| Waterproof | Heavy rain, exposure to wet environments | PU-coated or laminated fabrics | Seam-sealed or taped seams | High resistance — no water penetration in short exposure |

| Submersible | Full immersion, underwater use | RF-welded or TPU film-bonded materials | Welded construction (no stitching) | 100% sealed — capable of submersion |

2. Water-Resistant: The First Line of Defense

Water-resistant soft goods rely on DWR coatings that cause water to bead up and roll off the surface instead of soaking in. This is the most common treatment for backpacks, duffels, and apparel, offering light protection without adding cost or stiffness.

However, DWR is not permanent. Over time — and with washing or abrasion — its effectiveness fades. At studioFAR, we help clients test and select the right textile mill finishes and advise when a re-application or higher-grade coating is necessary for their product’s intended lifespan.

If your product will only see brief exposure to water — like a commuter backpack or stroller cover — water resistance may be all you need.

3. Waterproof: The Most Misunderstood Term in Soft Goods

“Waterproof” is where marketing claims often go wrong. A waterproof soft good typically features PU-coated or laminated fabrics (like 210D nylon with a polyurethane layer) combined with seam sealing or tape applications to block stitch holes.

For instance, PU zippers — commonly seen on outdoor and cycling gear — are coated to resist direct water penetration, but they’re not entirely waterproof under pressure or prolonged exposure. Even taped seams can eventually leak if not applied with the correct temperature, pressure, and seam allowance during production.

That’s why at studioFAR, we focus on design for manufacturing (DFM) and material validation — ensuring your factory’s construction techniques match your performance promise.

4. Submersible: True Waterproofing for Extreme Applications

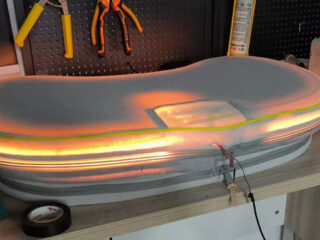

The only truly waterproof soft goods are submersible — meaning they can survive complete underwater immersion. These are built with RF (radio frequency) welding or heat-sealing technologies that fuse materials together without sewing.

Submersible construction is commonly used in marine bags, rescue gear, or dry sacks. It’s the most expensive and technically demanding method, but it guarantees a complete barrier to water ingress.

At studioFAR, we’ve developed RF-welded prototypes and TPU-film laminated constructions for clients needing uncompromising performance — ensuring every seam, zipper, and vent is carefully engineered for the environment it will face.

5. Choosing the Right Level of Protection

Selecting the correct waterproofing level isn’t about claiming “the best” — it’s about choosing the right protection for your market and user.

If your brand promises lightweight and breathable performance, you may not need full waterproofing. On the other hand, if your users are paddling, commuting in heavy rain, or working in demanding outdoor environments, then laminated or welded construction becomes essential.

The key is balancing material performance, manufacturing complexity, and cost. That’s where studioFAR’s expertise in soft goods prototyping, testing, and DFM helps clients make informed design decisions — long before production begins.

6. Final Thoughts: The Truth About “Waterproof” in Soft Goods

A soft good can be engineered to be highly water-resistant or virtually waterproof, but unless every seam and zipper is RF-welded, it’s never truly impermeable. That doesn’t mean every bag or garment needs to be submersible — it means your design must match its environment and user promise.

At studioFAR, we guide clients from material selection through prototype validation and production readiness, ensuring that performance claims align with real-world results.

If you’re developing an outdoor, baby, or lifestyle product that needs to perform in wet conditions, let’s discuss how to engineer the right level of protection from the start.

Feel free to schedule a call here: