In today’s fast-paced product world, successful brands move from concept to production faster than ever — without sacrificing quality. The key to that success often comes down to one crucial step: soft goods prototyping.

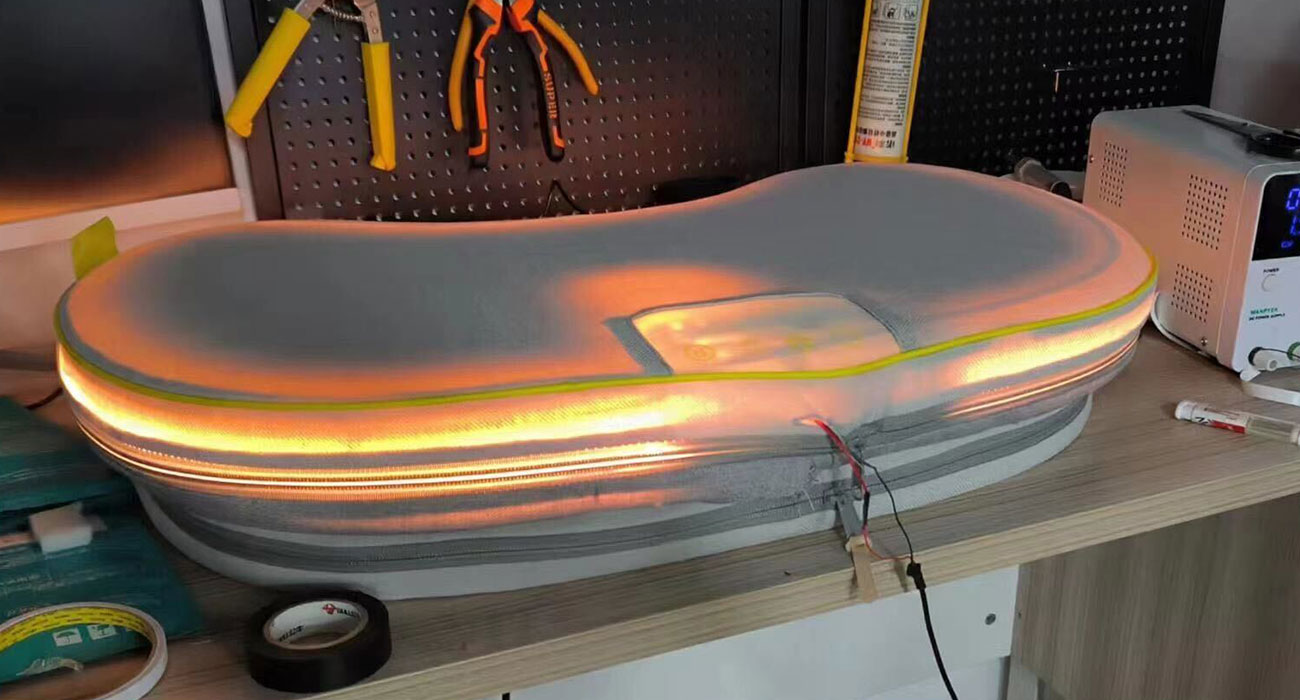

At studioFAR, we see the soft goods prototype as far more than a test model. It’s the moment where ideas become tangible — where design meets material, and form meets function. Whether you’re developing a wearable, travel accessory, or automotive interior, your prototype isn’t just part of the process — it is the process.

Why Prototyping Defines Success in Soft Goods Design

The difference between a clever idea and a commercially viable product often lies in how well it’s prototyped. Soft goods are complex — they bend, flex, and react differently depending on patterning, material choice, and construction technique. A digital rendering can’t tell you how a fabric behaves under tension, how a strap feels on the shoulder, or how a zipper moves around a curved seam.

Soft goods prototyping solves those unknowns. It validates every design decision before you invest in large-scale production — saving time, reducing costs, and improving product performance.

At studioFAR, our goal is to make your prototype feel like the final product — functional, refined, and ready for production evaluation.

The Phases of Soft Goods Prototyping

Our process is iterative, strategic, and rooted in real manufacturing insight. Below is a simplified breakdown of what a professional soft goods prototyping timeline looks like — and how it differs from the “DIY” or early startup approach that often leads to mistakes.

| Stage | DIY or Early Approach | studioFAR Prototyping Process | Why It Matters |

|---|---|---|---|

| Concept Sketch | Loose sketches, vague measurements | CAD-based sketches refined with ergonomic studies | Ensures proportions are realistic and manufacturable |

| Pattern Development | Made from guesswork or traced from existing products | Digitally drafted, then manually refined for precision | Patterns define product geometry and repeatability |

| Material Selection | Based on availability, not performance | Guided by CMF (Color, Material, Finish) testing and use-case | The right fabric impacts cost, comfort, and brand perception |

| Prototype Construction | Rough sample stitched without tolerances | Professional sewing with construction standards | Realistic fit, feel, and durability testing |

| Evaluation & Revision | Feedback from friends/family | Fit, function, and manufacturability analysis | Data-driven decisions before final design approval |

This comparison illustrates a core truth: the quality of your prototype determines the quality of your product.

At studioFAR, we approach every prototype as a tool for validation — testing not just aesthetics, but performance, production efficiency, and long-term usability.

Integrating CMF and Function Early

Color, Material, and Finish (CMF) considerations often happen too late in the process. But at studioFAR, CMF decisions are baked into soft goods prototyping from the very beginning.

Why? Because materials behave differently. The same pattern made in Cordura nylon versus recycled polyester will drape, fold, and feel completely unique. By experimenting early, we optimize for both manufacturability and brand expression.

We also explore color combinations and finishes that align with your brand — from eco-conscious fabrics for baby gear to high-durability textiles for EV accessories. Every prototype becomes a material study — a chance to balance sustainability, style, and function.

The Role of AI and Digital Tools in Modern Prototyping

Digital innovation, including AI-assisted design tools, is changing how we prototype. At studioFAR, we use AI for concept generation, pattern visualization, and design comparison, helping us identify creative directions faster.

However, we’re clear on one principle: AI doesn’t replace hands-on prototyping — it enhances it. A digital model can’t replicate how a fabric puckers after sewing or how a zipper aligns under tension. The tactile, human understanding of materials is still irreplaceable.

By combining AI visualization with physical craftsmanship, we reduce development time without sacrificing the artistry that makes great soft goods stand out.

Prototyping for Manufacturing Efficiency

One of the most overlooked benefits of soft goods prototyping is its impact on manufacturing readiness. A refined prototype is more than a presentation sample — it’s the foundation for your tech pack, DFM (Design for Manufacturing) documentation, and ultimately your production tooling.

At studioFAR, our prototypes are designed for real-world scalability:

-

Pattern precision reduces sewing time and material waste.

-

Hardware alignment ensures consistency in production runs.

-

Material testing verifies compatibility with cutting and bonding processes.

-

Factory collaboration during prototyping prevents rework later.

In short: a better prototype means a smoother launch.

The Payoff: Fewer Mistakes, Faster Launch, Better Product

Too many startups skip professional prototyping, only to face costly corrections later. We’ve seen products go through three or four manufacturing rounds because the prototype wasn’t tested properly.

By investing in a professionally built soft goods prototype, brands gain clarity — and confidence. It becomes your roadmap to a successful launch.

At studioFAR, our clients consistently find that a well-executed prototype shortens their timeline to production, improves product quality, and builds credibility with investors, retailers, and consumers alike.

Final Thoughts

The next time you start developing a bag, wearable, or soft goods product, think of your prototype not as a test, but as the first version of your success.

Soft goods prototyping is the single most valuable stage in the design process — and it’s where the experience of a studio like studioFAR makes all the difference.

From pattern development and CMF selection to manufacturing consultation, we bridge design and production seamlessly, helping clients create products that are both beautiful and buildable.

If you’re ready to bring your idea to life with a professional soft goods prototype, reach out — we’ll help you turn that vision into something you can hold, test, and proudly launch.

Contact Fernando A. Robert, Director of studioFAR, and let’s discuss how we can bring your baby product idea to life.

Feel free to schedule a call here: