When most entrepreneurs think about launching a soft goods product, they picture the design, the materials, and the end-user experience. Rarely do they think about what happens once that product is ready to leave the factory. But in today’s world of rising logistics costs and global supply chain complexity, designing for shipping is just as important as designing for function, style, and durability.

At studioFAR, we’ve seen how design for manufacturing (DFM) and design for shipping go hand-in-hand. Your product may look beautiful and perform perfectly, but if it’s too bulky, expensive to ship, or difficult to pack efficiently, your margins can take a serious hit. Let’s explore how smart soft goods prototyping and thoughtful engineering can help you save money, reduce waste, and get your product to market with less friction.

The Rising Cost of Shipping and Why It Matters

Over the past few years, global shipping costs have skyrocketed. Freight rates, dimensional weight pricing, and last-mile delivery fees have become a major factor in the profitability of physical products. For soft goods entrepreneurs working with tight margins, this can be the difference between a successful launch and a stalled business.

Designing for shipping starts with acknowledging that every extra inch of packaging costs money — whether you’re shipping internationally, domestically, or fulfilling e-commerce orders from your own warehouse. Bulky products not only cost more to ship but also take up more space in storage, impacting inventory costs. By considering shipping during the design phase, you can minimize these costs before they become a problem.

Designing Soft Goods to Collapse and Pack Efficiently

One of the biggest advantages of soft goods is their inherent flexibility. Unlike hard goods, bags, luggage, wearables, and other textile-based products can often be designed to collapse, fold, or roll into a much smaller package. This means you can maximize the number of units that fit into a single shipping container, significantly reducing freight cost per unit.

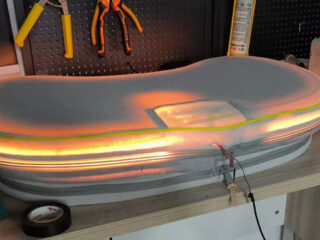

During the prototyping phase, we often explore multiple approaches to construction to see which delivers the smallest possible shipping volume without compromising durability or user experience. Sometimes it’s as simple as selecting a different foam thickness, rethinking the internal frame structure, or choosing hardware that nests efficiently.

Collapsibility isn’t just about shipping from the factory — it can also reduce e-commerce fulfillment costs. A smaller box or polybag means lower dimensional weight pricing from carriers like UPS, FedEx, and DHL. This directly impacts your profit margin per order.

Balancing Aesthetics, Functionality, and Shipping

Of course, there’s always a balance to strike between aesthetics and shipping efficiency. A product designed purely for compact shipping might look or feel flimsy once unpacked, so design for shipping must work in harmony with your brand’s desired user experience.

At studioFAR, we approach this by integrating design for manufacturing and shipping considerations early in the process. During soft goods prototyping, we test different packaging configurations alongside different material options. This helps our clients avoid surprises later in the development cycle — when changes become more expensive and disruptive.

Our goal is to create a product that feels premium, functions perfectly, and also ships efficiently. This is especially critical for brands selling online, where consumers now expect free or low-cost shipping. Every dollar saved in logistics can go back into marketing, R&D, or profit.

How Design for Shipping Impacts Sustainability

Another major benefit of designing for shipping is its impact on sustainability. Smaller packaging means fewer resources used in shipping, lower carbon emissions per unit, and less waste for the consumer to deal with. In a world where brands are increasingly being judged on their environmental footprint, this can be a differentiator that builds trust with your audience.

For example, a baby carrier designed to fold into a compact pouch not only saves you money on shipping but also delights your customers with clever storage and portability. This type of design detail can be highlighted in your marketing, turning a cost-saving decision into a feature that excites buyers.

Why You Need an Expert Partner

If you’re developing a soft goods product, shipping should never be an afterthought. The earlier you incorporate it into your product development process, the more money and headaches you’ll save.

At studioFAR, we combine soft goods design expertise, DFM knowledge, and hands-on prototyping experience to ensure your product is optimized for production, packaging, and shipping. We guide you through material selection, internal construction, and packaging design so that when your product is ready to launch, you’re not blindsided by unexpected costs or logistics challenges.

Designing for shipping is not just a technical consideration — it’s a strategic one that can impact your profitability, customer satisfaction, and scalability.

Final Thoughts

Designing a soft good product that looks great and works well is only half the battle. To build a truly successful brand, you must also design with logistics in mind. Shipping efficiency, packaging size, and collapsibility all play a crucial role in the success of your business — especially in today’s competitive e-commerce environment.

If you’re developing a bag, wearable, or other soft goods product and want to avoid costly surprises in shipping and fulfillment, let’s talk. At studioFAR, we help entrepreneurs and brands go from prototype to production with confidence — and that includes designing for shipping.

Contact Fernando A. Robert, Director of studioFAR, and let’s discuss how we can bring your baby product idea to life.

Feel free to schedule a call here: